Overview

1. Customized product development

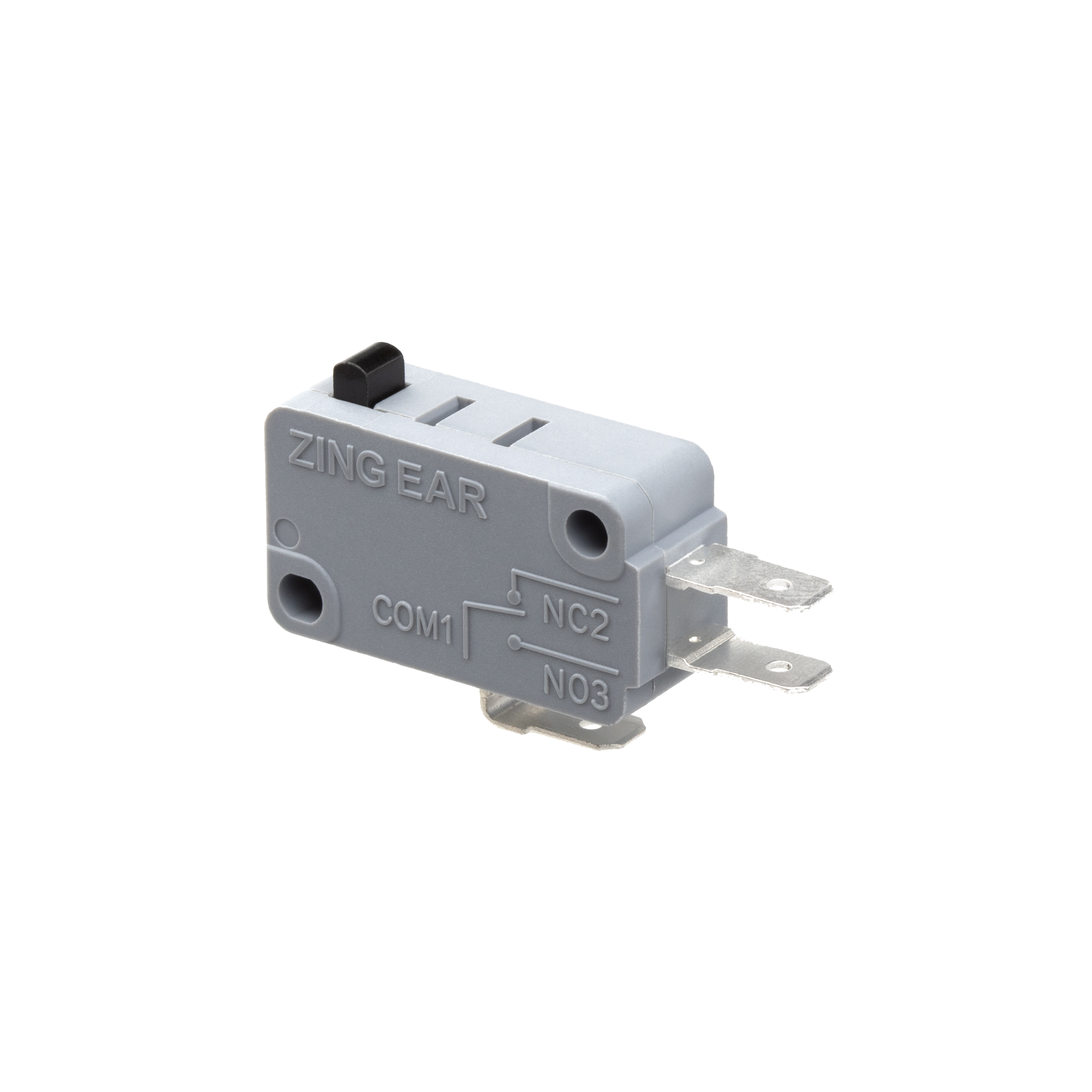

Oil-resistant design: Adopting IP65 protection level to prevent oil stains from penetrating and causing oxidation of contacts.

Silent optimization: Action noise < 25dB, enhancing user experience (ordinary switches typically have 30-40dB).

High-precision triggering: Travel tolerance controlled within ±0.05mm to avoid false judgment by the baffle.

2. Rigorous Testing Verification

High-temperature and high-humidity test: Operates continuously for 1000 times without failure under an environment of 85℃/85%RH.

Life test: Passes a 100,000-cycle mechanical life test (industry standard is 50,000 cycles).

Chemical corrosion test: Resists repeated wiping with cleaning agents and the contacts show no corrosion.

3. Intelligent Function Integration

Interlinked Control: The signal from the microswitch is synchronized with the automatic speed adjustment function of the smoke machine.

Safety Protection: When the damper is not closed, the power is automatically cut off and an alarm is triggered.

Project Outcomes and Advantages

Enhanced Product Reliability: Failure rate reduced to 0.01% (industry average 0.1%).

Energy Saving Optimization: Standby power consumption decreased by 30% (achieved through the design of low-power microswitches).

User Satisfaction: Silent operation and precise triggering received positive feedback from Electrolux terminals.

Advantages

-

01Environmental protection leadership100% lead-free process; Compliant with EU RoHS 3.0; Recycling rate > 90%!

-

02Energy efficiency innovationStandby power consumption: 0.5 μA (industry standard: 5 μA) Self-generating switch technology Carbon footprint reduction: 40%